Double flank gear roll testing

Double-flank gear roll testing is a method of quick, reliable and inexpensive measuring of gears. It helps you indetify damaged parts in your batch, provides with data of double-flank deviations, fluctuation of axis distance as well as information of the radial runout.

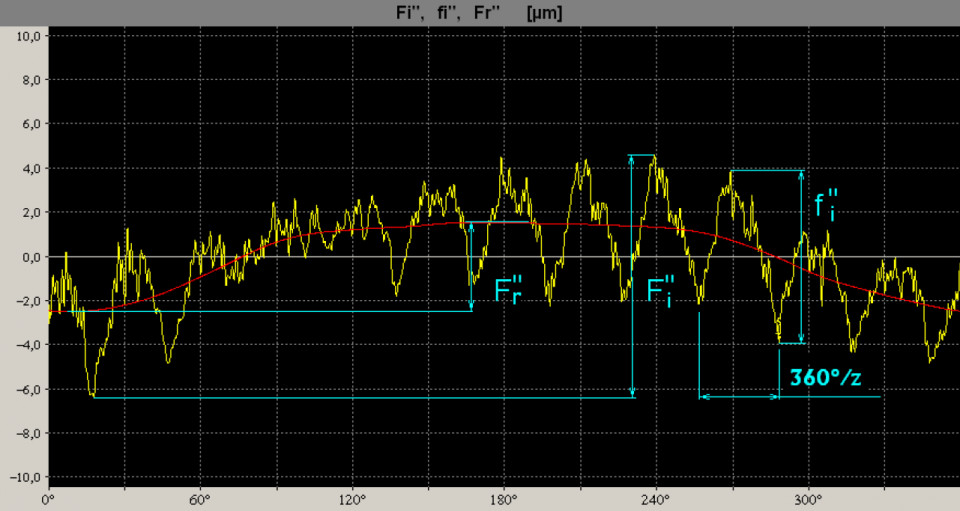

Following deviations are measured and evalutated:

- Fi" - total composite error

- fi" - tooth to tooth composite error

- Fr" - average value of radial runout

Other measurable and evaluable devations:

- j - backlash

- Aa" - fluctuation of axis distance

- Mz" - measure over teeth

- Mdk" - Measure over pins/balls

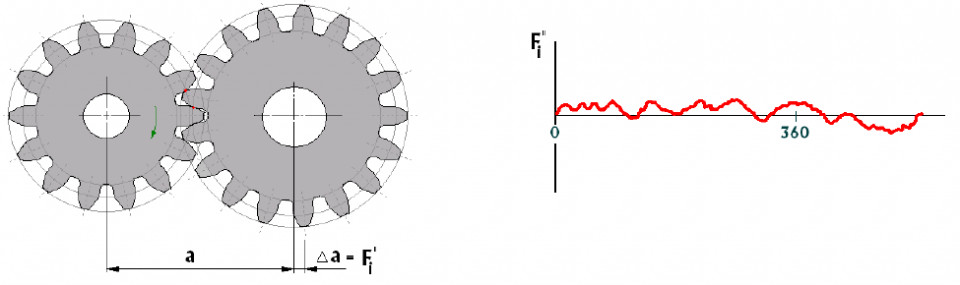

Double-flank gear roll testing inspects your gears flanks (left and right) simultaneously with constant force in radial direction. Tooth error(s) causes deviation of axis distance which is evaluated by well-known standards (DIN, ISO, AGMA, JIS, JGMA, BS, etc.).